Molybdenum Thermal Spray Wire e hloekileng bakeng sa Galling le Scuffing Resistance

Mofuta le Boholo

Zhaolixin Tungtsen & Molybdenum e ka fana ka terata ea molybdenum ho latela litšoantšo le litlhoko tsa hau.

| Diameter (μm) | Boima (mg/200mm) | Boima ba 'mele (mg/200mg) Mamello (%) | Mamello ea Diameter (%) | ||

| Sehlopha sa 1 | Sehlopha sa 2 | Sehlopha sa 1 | Sehlopha sa 2 | ||

| 20≤d <30 | 0.65 ~ 1.47 | ±2.5 | ±3 | ||

| 30≤d <40 | > 1.47 ~ 2.61 | ±2.0 | ±3 | ||

| 40≤d <100 | >2.61–16.33 | ±1.5 | ±3 | ||

| 100≤d <400 | >16.33~256.2 | ±1.5 | ±4 | ||

| 400≤d <600 | ±1.5 | ±2.5 | |||

| 600≤d <3200 | ±1.0 | ±2.0 | |||

Likaroloana

| Thepa | Metric | Moemphera |

| Matla a tsitsipano (a anneal) | 324 MPa | 47000 psi |

| Matla a ho kuta (sekhahla sa khatello ea maikutlo 0.25/s) | 500 MPa | 72500 psi |

| Matla a chai a hatellang (kotulo ea 0.01%) | 400 MPa | 58000 psi |

| Modulus ea elasticity | 330 GPA | 47900 ksi |

| Modulus ea elasticity mochesong o phahameng (@2000°C/3630°F) | 160 GPA | 23200 lik'hilograma |

| Katoloso ea Thermal Coefficient: | 5 x 10-6 cm/cm @ 25 oC | |

| Khokahano ea Motlakase: | 34% ea IACS | |

| Thermal Conductivity: | 1.38 W/cm/K @ 298.2 K | |

| Ho hanyetsa Motlakase: | 5.2 microhm-cm @ 0 oC | |

Mo-wire ke botšo bo tloaelehileng bo koahetsoeng ka graphite.Ka mor'a hore graphite e tlosoe ke metallic luster.

Lisebelisoa

- Bakeng sa mochini oa ho itšeha oa terata

- Bakeng sa ho hlahisa likarolo tsa mohloli oa leseli la motlakase le likarolo tsa vaccum ea motlakase

- Bakeng sa ho hlahisa likarolo tsa ho futhumatsa le likarolo tsa refractory liboping tse phahameng tsa mocheso

- Bakeng sa ho fafatsa likarolo tse senyehang tsa koloi le mochini o mong ho ntlafatsa boleng ba tsona

- La2O3 kapa Y2O3 doped Refractory Mo-wire lia fumaneha

Mosebetsi oa matsoho

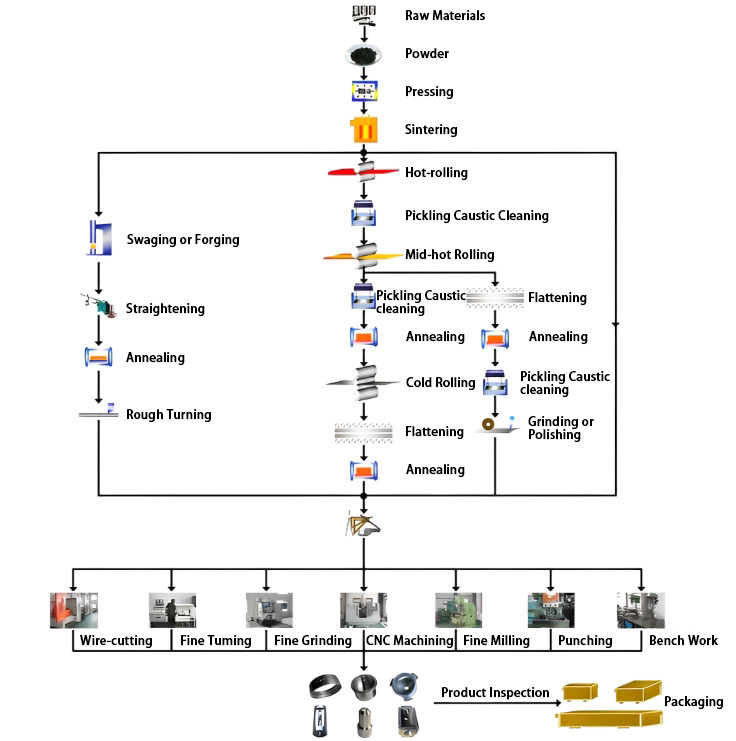

Lisebelisoa tse so ntlafatsoe:Ho qala ka lihlahisoa tse tala, re khetha lisebelisoa tsa boleng bo phahameng, tse hlahelletseng haholo ka botsitso le botsitso ba lihlahisoa.Hlalosa mefuta e fapaneng ea thepa e tala 'me u tšoaee nomoro ea batch.'Me sehlopha se seng le se seng sa lisebelisoa tse tala se tla nkoa, se hlahlojoe le ho bolokoa.Etsa bonnete ba hore sehlahisoa se seng le se seng se felile se fumaneha hape 'me u tsoele pele ho ntlafatsa boleng ba sehlahisoa.

Phofo:Taolo ea ts'ebetso ea ho sila ea lihlahisoa tsa Zhaolinxin Metal e nepahetse haholo, e nang le li-mixer tse 'maloa tse kholo le sethala sa vibration ho netefatsa hore lisebelisoa tse ts'ebetsong ea ho phunya le ho kopanya li ka hlohlelletsoa ka botlalo le ho ajoa ka mokhoa o ts'oanang, e le ho etsa bonnete ba hore mokhatlo o hlophisitsoeng oa kahare o lumellana. lihlahisoa.

Ho hatella:Ts'ebetsong ea ho kopanya phofo, phofo e hatelloa ke lisebelisoa tsa ho hatella tsa isostatic ho etsa hore sebopeho sa eona sa ka hare se tšoane le se teteaneng.Zhaolixin e na le hlobo e phethahetseng haholo ea batch, hape e na le lisebelisoa tsa khatiso tsa isostatic ho kopana le tlhahiso ea lihlahisoa tse kholo haholo.

Sintering:Ka metallurgy ea phofo, ka mor'a hore phofo ea tšepe e thehoe ka ho hatelloa ha isostatic, e futhumetse ka mocheso o tlase ho feta ntlha ea ho qhibiliha ea likarolo tse kholo ho etsa hore likaroloana li kopane, e le ho ntlafatsa ts'ebetso ea lihlahisoa, tse bitsoang sintering.Ka mor'a hore phofo e thehoe, 'mele o teteaneng o fumanoang ka sintering ke mofuta oa thepa ea polycrystalline.Sintering tshebetso ka ho toba ama lijo-thollo boholo, pore boholo le lijo-thollo moeli sebopeho le kabo ka microstructure, e leng tshebetso ya konokono ea phofo metallurgy.

Ho qapa:Ts'ebetso ea ho qhekella e ka etsa hore thepa e fumane sekhahla se phahameng, thepa e ntle ea mochini, 'me e be le karolo ho matlafatsang bokaholimo.Taolo e nepahetseng ea sekhahla sa ts'ebetso le mocheso oa forging oa thepa ea tungsten le molybdenum ke ntlha ea bohlokoa bakeng sa ts'ebetso e phahameng ea Zhaolixin tungsten le thepa ea molybdenum.Mokhoa oa ho sebetsa oa ho sebelisa mochini oa forging ho kenya khatello ho tšepe e se nang letho ho e holofatsa ka polasetiki ho fumana forging e nang le thepa e itseng ea mochini, sebopeho le boholo bo itseng.

Rolling:Mokhoa oa ho roala o etsa hore lisebelisoa tsa tšepe li hlahise deformation ea polasetiki e tsoelang pele tlas'a khatello ea moqolo o potolohang, 'me u fumane sebopeho le thepa e hlokahalang ea karolo.Ka theknoloji e tsoetseng pele ea tungsten le molybdenum e batang le e chesang e futhumatsang le lisebelisoa, ho tloha ho tungsten le tšepe ea molybdenum e se nang letho ho isa tlhahiso ea foil ea tungsten le molybdenum, Zhaolixinguarante e u fa theknoloji e tsoetseng pele ea tlhahiso le thepa e phahameng ea tšepe.

Phekolo ea Mocheso:Ka mor'a ts'ebetso ea ho qhekella le ho roala, thepa e tlas'a ts'ebetso ea phekolo ea mocheso ho felisa ka ho feletseng khatello ea kelello ea ka hare ea thepa, ho fana ka papali ea ts'ebetso ea thepa, le ho etsa hore thepa e be bonolo bakeng sa machining e latelang.Zhaolixin e na le libopi tse ngata tsa vacuum le lisebelisoa tsa hydrogen tsa kalafo ea mocheso ho kopana le phano e potlakileng ea litaelo tsa tlhahiso ea bongata.

Mochini:Thepa ea Zhaolixin e se e fumane phekolo e feletseng ea mocheso, ebe e sebelisoa ka boholo bo fapaneng bo hlophisitsoeng ka lisebelisoa tsa machining tse kang ho fetola, ho sila, ho itšeha, ho sila, joalo-joalo, 'me ho tiisa hore mokhatlo o ka hare oa thepa ea tungsten le molybdenum e thata, ha e na khatello ea kelello. le sekoti se se nang masoba, se ka khotsofatsang litlhoko tsa bareki.

Netefaletso ea boleng:Tlhahlobo le taolo ea boleng li tla etsoa ho tsoa ho lisebelisoa tse tala le mohato o mong le o mong oa tlhahiso, e le ho tsoela pele ho netefatsa boleng ba sehlahisoa se seng le se seng.Ka nako e ts'oanang, ha lihlahisoa tse phethiloeng li fanoa ho tloha ntlong ea polokelo, ponahalo, boholo le mokhatlo oa ka hare oa thepa li lekoa ka bonngoe.Ka hona, botsitso le botsitso ba lihlahisoa li hlahella ka ho khetheha.