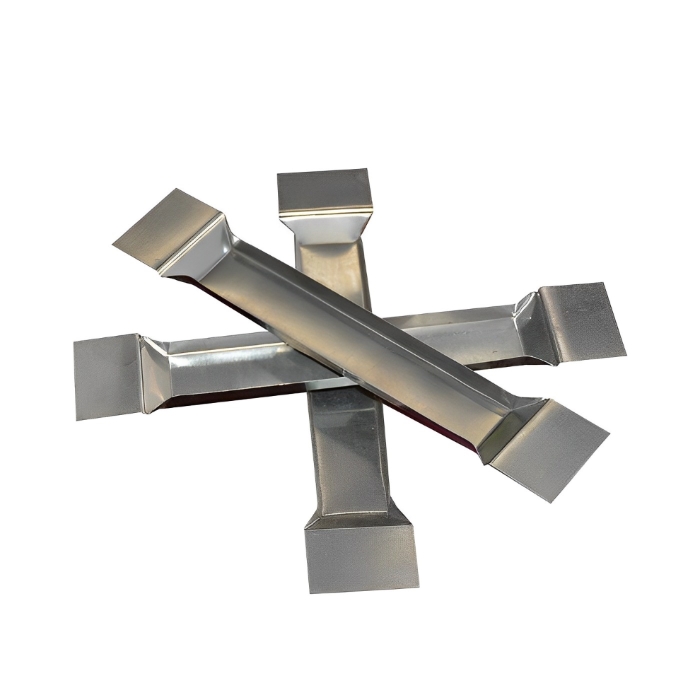

Customized Tungsten Boats Bakeng sa Vacuum Coating

Mofuta le Boholo

| dikahare | boholo (mm) | Bolelele ba slot (mm) | Botebo ba Slot(mm) |

| sekepe sa tungsten | 0.2*10*100 | 50 | 2 |

| 0.2*15*100 | 50 | 7 | |

| 0.2*25*118 | 80 | 10 | |

| 0.3*10*100 | 50 | 2 | |

| 0.3*12*100 | 50 | 2 | |

| 0.3*15*100 | 50 | 7 | |

| 0.3*18*120 | 70 | 3 | |

| Tlhokomeliso: Mefuta e khethehileng e ka etsoa ho latela litlhoko tsa bareki | |||

Likaroloana

Sekepe sa Tungsten se sebelisetsoa vacuum evaporator ea lisebelisoa tsa granular.Likepe tsa Tungsten le tsona li ka sebelisoa ho etsa mouoane lithapo tse tšesaane, tse khutšoane kapa lithapo tse metsi.Sekepe sa Tungsten evaporation se loketse mosebetsi oa liteko kapa oa ho etsa mohlala ka sistimi e nyane ea mouoane, joalo ka nkho ea tšepe.Joalo ka sets'oants'o se ikhethileng se bōpehileng joaloka seketsoana, seketsoana sa tungsten se sebelisoa haholo ho fafatsa mahlaseli a elektrone, ho sinta le ho anneal ka vacuum coating.

Sekepe sa Tungsten evaporation se etsoa ka mohala o khethehileng oa tlhahiso;k'hamphani ea rona e ka fana ka bareki ka lihlahisoa tsa boleng bo holimo.Re netefatsa hore thepa e tala ea tungsten eo re e sebelisang e hloekile haholo.Theknoloji e tsoetseng pele le mekhoa e khethehileng ea phekolo e sebelisoa ho phekola lihlahisoa tsa rona.Khamphani ea rona e ka hlahisa seketsoana sa tungsten bakeng sa mouoane oa vacuum ho latela lits'oants'o tsa bareki.

Lisebelisoa

Sekepe sa Tungsten se ka sebelisoa indastering e bobebe, indastering ea elektroniki, indastering ea sesole, indastering ea semiconductor: ho roala, li-ceramics tse nepahetseng tsa sintering, sintering ea capacitor, nkho ea tšepe, ho fafatsa borokho ba elektrone.Sepheo sa tlhahlobo ea X-ray, crucible, heat element, X-ray radiation thebe, sputtering target, electrode, semiconductor base plate, le electron tube component, emission cathode ea electron beam evaporation, le cathode le anode ea ion implanter.