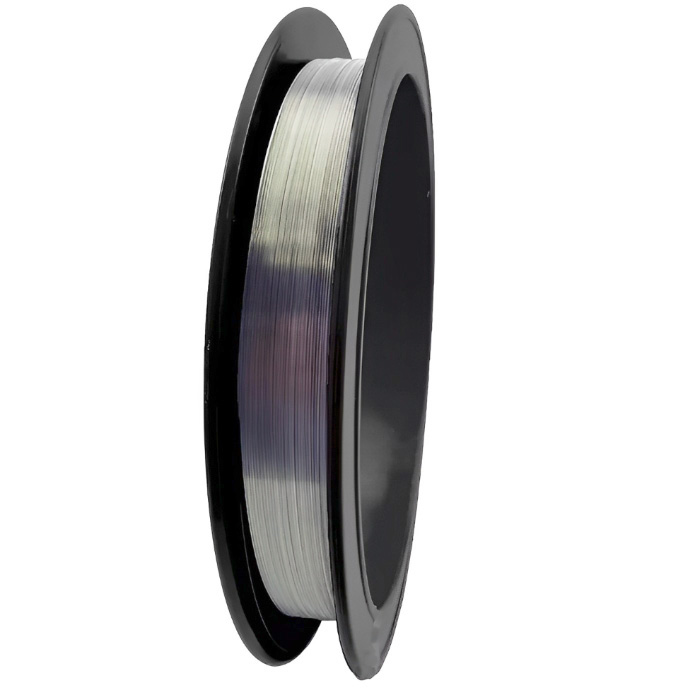

Bohloeki ba Boleng bo Phahameng 99.95% Tungsten Wire

Mofuta le Boholo

W-wire ke botšo bo tloaelehileng bo koahetsoeng ka graphite.Ka mor'a hore graphite e tlosoe ke metallic luster.

| Khethollo | Litaba tsa Tungsten | Likahare tsa Lintho tse sa hloekang | |

| Kakaretso | Emong le emong | ||

| WAL1, WAL2 | ≥99.95% | ≤0.05% | ≤0.01% |

| W1 | ≥99.95% | ≤0.05% | ≤0.01% |

| W2 | ≥99.92% | ≤0.08% | ≤0.01% |

| Tlhokomeliso: Potassium ha e baloe linthong tse litšila. | |||

Mamello ka bophara(%):

| Diameter (μm) | Boima (mg/200mm) | Boima ba 'mele(mg/200mm) Mamello(%) | Mamello ea Diameter(%) | ||||

| Sehlopha sa 0 | Sehlopha sa 1 | Sehlopha sa 2 | Sehlopha sa 0 | Sehlopha sa 1 | Sehlopha sa 2 | ||

| 5≤d≤12 | 0.075~0.44 | - | ±4 | ±5 | - | - | - |

| 12 | >0.44~0.98 | - | ±3 | ±4 | - | - | - |

| 18 | >0.98~4,85 | ±2 | ±2.5 | ±3 | - | - | - |

| 40 | >4.85–19.39 | ±1.5 | ±2.0 | ±2.5 | - | - | - |

| 80 | >19.39–272.71 | ±1.0 | ±1.5 | ±2.0 | - | - | - |

| 300 | >272.71~371.79 | - | ±1.0 | ±1.5 | - | - | - |

| 350 | - | - | ±1.5 | ±2.0 | ±2.5 | ||

| 500 | - | - | ±1.0 | ±1.5 | ±2.0 | ||

Mokhoa oa tekheniki:

Tungsten Powder → Isostatic Pressing → Bar Billet →Sintering → Semi e felileng → Forging→ Swaging → Drawbench → Lihlahisoa tsa ho qetela → Tlhahlobo → Ho paka

Likaroloana

1.Ponahalo e phahameng ea ho qhibiliha le khanyetso e phahameng ea kutu

2. Ts'ebetso e phahameng ea mocheso

3. 99.95% Bohloeki

4. Ponahalo: silevera e tšoeu / bohlooho tšepe e benyang Bokaholimo ba terata ea tungsten e bentšitsoeng ka electrolytic e tla ba boreleli, e hloekile, e le silevera e bohlooho e nang le tšepe e phatsimang.Mohala oa tungsten o na le sebopeho se setle haholo, bophelo bo bokhuts'oane le katleho ea mabone a lijo tsa mantsiboea.

Lisebelisoa

1. Ho hlahisa likarolo tsa mohloli oa leseli la motlakase le likarolo tsa ente ea motlakase;

2. Ho hlahisa likarolo tsa ho futhumatsa le likarolo tse refractory liboping tse phahameng tsa mocheso;

3. Ho hlahisa lintho tse futhumatsang tse sebelisoang ka vaccum metalizing kapa plating.