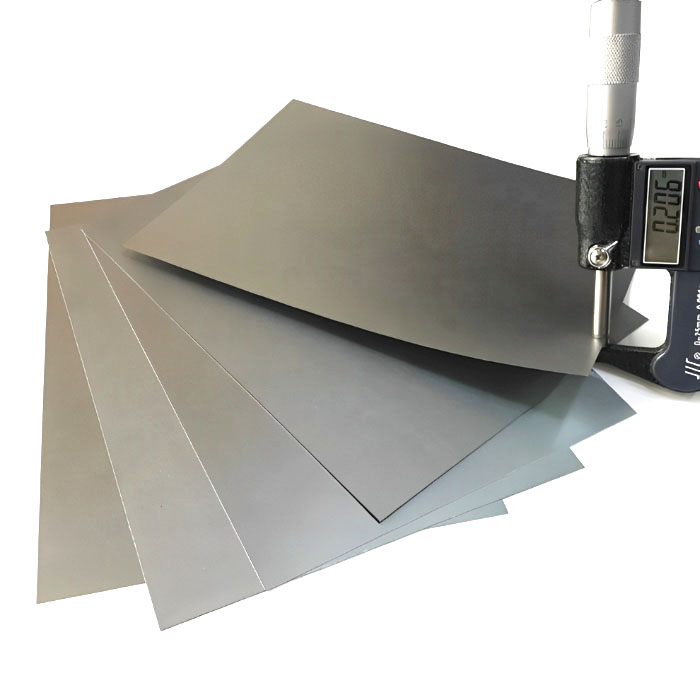

Tungsten Heavy Alloy (WNIFE) Rod

Tlhaloso

Boima ba tungsten heavy alloy rod bo tloha ho 16.7g/cm3 ho isa ho 18.8g/cm3.Boima ba eona bo phahame ho feta melamu e meng.Melamu ea alloy e boima ea Tungsten e na le litšobotsi tsa mocheso o phahameng le ho hanyetsa kutu.Ntle le moo, melamu e boima ea alloy ea tungsten e na le khanyetso e phahameng haholo le polasetiki ea mochini.

Hangata lithupa tsa alloy tsa Tungsten li sebelisoa ho etsa likarolo tsa hamore, tšireletso ea mahlaseli, lisebelisoa tsa tšireletso ea sesole, lithupa tsa welding le mehlala ea extrusion.Hape ke e 'ngoe ea lisebelisoa tsa ho hlahisa libetsa le lithunya.

Thepa

| Thepa ea Boima le Boima, ASTM B777 | |||

| Sehlopha | Tungsten Purity, % | Boima ba 'mele, g/cc | Hardness, Rockwell"C", max |

| Sehlopha sa 1 | 90 | 16.85-17.25 | 32 |

| Sehlopha sa 2 | 92.5 | 17.15-17.85 | 33 |

| Sehlopha sa 3 | 95 | 17.75-18.35 | 34 |

| Sehlopha sa 4 | 97 | 18.25-18.85 | 35 |

| Haholo-holo tungsten e eketsa phofo e kang koporo, nickel kapa tšepe. | |||

| Echanical Properties, ASTM B777 | ||||||

| Sehlopha | Tungsten Purity, % | Matla a ho qetela a Tensile | Kotulo e Matla ho 0.2% Off-set | Elongation,% | ||

| ksi | MPa | ksi | MPa | |||

| Sehlopha sa 1 | 90 | 110 ksi | 758 MPa | 75 ksi | 517 MPa | 5% |

| Sehlopha sa 2 | 92.5 | 110 ksi | 758 MPa | 75 ksi | 517 MPa | 5% |

| Sehlopha sa 3 | 95 | 105 ksi | 724 MPa | 75 ksi | 517 MPa | 3% |

| Sehlopha sa 4 | 97 | 100 ksi | 689 MPa | 75 ksi | 517 MPa | 2% |

| Haholo-holo tungsten e eketsa phofo e kang koporo, nickel kapa tšepe. | ||||||

Likaroloana

Ntle le sekhahla se phahameng le ho monya mahlaseli a kotsi, thepa e ngata ea bohlokoa e amanang le boima bo phahameng le ho hanyetsa li sebelisitsoe palo e kholo ea likopo.Tungsten heavy alloy ke ea li-alloys tsa tšepe tse refractory tse hanyetsanang le mocheso le ho khathala ka mokhoa o makatsang.Alloy e boima ea Tungsten e sebelisitsoe haholo-holo ho etsa likarolo tse hlokang khanyetso e phahameng, joalo ka lisebelisoa tsa machining, ho kenyelletsa le lathe le dice.

E fumana ho fokotseha hanyenyane litšobotsing tsa eona esita le ka mocheso o phahameng 'me e na le khanyetso e babatsehang ea ho apara.Ka hona, li-alloys tsa Tungsten li sebelisoa bakeng sa lisebelisoa tsa machining tse kang lathes, mechini ea ho sila, joalo-joalo, le ho etsa likarolo tsa koloi tse kang lienjineri, phetisetso, setataiso, joalo-joalo, tse kenyang letsoho ntlafatsong ea ho nepahala ha mochini.

Katoloso e tlase ea mocheso

High thermal le motlakase conductivity

Khanyetso e phahameng ea arc

Tšebeliso e tlaase

Lisebelisoa

Tungsten heavy alloy e sebetsa hantle lits'ebetsong tse hlokang ts'ebetso e phahameng ea ho hanyetsa kutu, density, machinability, le ts'ireletso ea mahlaseli.Ka hona, sena se etsa hore e be se loketseng bakeng sa ho sebelisoa liindastering tse itseng tsa ho etsa litšepe, tsa meepo, tsa sefofane le tsa bongaka.